When shipping temperature-sensitive goods, dry ice is often the go-to cooling solution. But how long do dry ice packs last? Is it 24, 48, or 72 hours? The answer depends on several variables like the amount of dry ice used, the quality of insulation, and the environmental conditions during transit. In this guide, we’ll break down the factors that influence dry ice lifespan, give you best practices to optimize its duration, and help you decide when dry ice is the right choice for your shipment.

-

What factors determine whether a dry ice pack lasts 24, 48, or 72 hours?

-

How much dry ice should you use, and how does insulation affect its longevity?

-

When should you consider using gel packs or phase change materials (PCMs) instead of dry ice?

-

What 2025 regulations and safety rules apply to dry ice shipments?

-

How do new technologies extend dry ice hold times?

What Affects the Duration of Dry Ice Packs?

Why Does Dry Ice Duration Vary So Much?

Dry ice sublimates (transforms from solid to gas) at -78.5°C. Several factors control the sublimation rate:

-

Amount of Dry Ice: More dry ice equals longer cooling durations. Generally, 5–10 pounds of dry ice sublimate every 24 hours under standard conditions.

-

Packaging and Insulation: Well-insulated containers slow down the heat transfer into the box, preventing rapid sublimation.

-

Ambient Temperature: Hotter climates cause dry ice to sublimate faster. If the shipping route passes through warm areas, more dry ice and better insulation are required.

Estimated Durations Based on Conditions:

| Dry Ice Quantity | Estimated Duration |

|---|---|

| 5–10 lbs | Up to 24 hours |

| 8–10 lbs | Up to 48 hours |

| 10–15 lbs | Up to 72 hours |

Pro Tip: Always plan for a buffer—add 10-25% more dry ice to cover unexpected delays or temperature fluctuations.

How Much Dry Ice Is Required?

How Do You Calculate Dry Ice Needs?

To determine how much dry ice you’ll need, consider the following guidelines:

-

For 24-Hour Shipments: 5-10 pounds of dry ice should suffice.

-

For 48-Hour Shipments: Double the amount of dry ice (10-20 pounds).

-

For 72-Hour Shipments: Plan for 20-30 pounds of dry ice, especially if shipping in warmer climates.

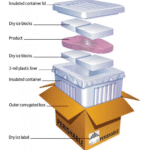

The Role of Packaging and Insulation

Packaging Types for Dry Ice:

-

Standard Dry Ice Bags: Good for short shipments (24-48 hours) but may not provide long-lasting cooling.

-

Foil-Lined Bags: Provide better insulation for longer trips (48-72 hours).

-

Insulated Boxes: Ideal for shipments requiring temperature control over extended periods, such as pharmaceutical products.

Tip: Always choose the right packaging for your shipment’s duration and temperature requirements.

Should You Switch to Gel Packs or PCMs?

While dry ice is ideal for freezing temperatures, alternative solutions like gel packs and phase change materials (PCMs) are becoming increasingly popular.

When to Use Alternatives:

-

Gel Packs: Best for products that need to remain cool (2-8°C) but not frozen.

-

PCMs: Suitable for shipments requiring consistent cooling but not extreme low temperatures. These materials are non-hazardous and reusable, offering a more sustainable solution.

Dry Ice vs. Alternatives:

| Feature | Dry Ice | Gel Packs | PCMs |

|---|---|---|---|

| Temperature | ≤ -78.5°C | 2°C to 8°C | Varies (typically 2–8°C) |

| Duration | 24–72 hours | 12–48 hours | Up to 72 hours |

| Cost | Moderate | Low | Moderate to High |

| Best For | Frozen goods | Refrigerated items | Temperature-sensitive goods |

Pro Tip: When shipping ultra-sensitive items like vaccines, consider using PCMs for better stability and regulatory compliance.

2025 Trends in Dry Ice Shipping

The dry ice shipping industry is evolving in response to new regulations, sustainability concerns, and technological advances.

Key 2025 Trends:

-

Smart Packaging: Temperature sensors and IoT devices are becoming standard in shipments, providing real-time monitoring of dry ice levels and temperatures.

-

Sustainability: Biodegradable and recyclable materials are gaining traction, offering a greener alternative to traditional dry ice packaging.

-

Hybrid Cooling Solutions: Combining dry ice with PCMs to maintain temperature stability for extended periods.

Commonly Asked Questions

How much dry ice do I need for a 24-hour shipment?

For a 24-hour shipment, typically 6-7 pounds of dry ice is required in an EPS liner or 4-5 pounds in a VIP system.

Can dry ice keep products frozen for 72 hours?

Yes, but you’ll need 15-30 pounds of dry ice, depending on insulation and ambient temperatures.

When should I use PCM or gel packs instead of dry ice?

For shipments under 72 hours that require temperatures between 2-8°C, PCM or gel packs are ideal. Dry ice is necessary for deep freeze conditions.

Conclusion and Recommendations

Understanding how long dry ice lasts is crucial for ensuring the safe transport of perishable goods. The longevity of dry ice packs depends on factors like the amount of dry ice used, packaging quality, and environmental conditions.

Action Steps:

-

Assess your shipment’s needs based on travel duration and product sensitivity.

-

Choose the appropriate packaging to match your shipment’s duration.

-

Plan for sufficient dry ice and consider alternatives like PCMs or gel packs if freezing temperatures aren’t necessary.

By following these steps, you can ensure your products stay at the right temperature during transit, optimize shipping costs, and maintain compliance with industry regulations.

About Tempk

Tempk is a trusted leader in cold chain logistics, offering dry ice solutions designed for secure, temperature-sensitive shipments. Our products are engineered to maximize insulation efficiency, ensuring that your shipments stay cool throughout transit.

Contact us for expert advice on choosing the best dry ice solutions for your business needs.