Kimberly Clark Stay Dry Ice Pack: Ready for Cold Chain?

Updated: September 1, 2025. If you handle temperature‑sensitive deliveries, the kimberly clark stay dry ice pack can be handy—but it isn’t a one‑size‑fits‑all coolant. Below we show where it works, where it doesn’t, and what to use instead so your product arrives safe, dry, and within spec. Expect a ~2.5‑hour cold window in therapy use, and plan PCMs for 2–8 °C routes.

-

When is a stay‑dry ice bag enough? (last‑mile cold chain ice pack; clinic‑to‑home runs)

-

When do you need PCMs or qualified shippers? (2–8 °C gel pack conditioning)

-

How does the 3‑layer “stay‑dry” design cut condensation? (stay‑dry ice pack with ties)

-

Which alternative coolant should you choose by lane? (5 °C PCM pack; dry ice basics)

-

What changed in 2025—and how should you adapt? (recyclable thermal liner; reusable systems)

What is the Kimberly Clark Stay Dry Ice Pack—and when should you use it?

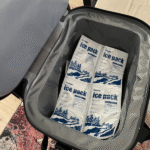

Short answer: The kimberly clark stay dry ice pack is a refillable, reusable medical ice bag built with a soft outer, absorbent middle, and film inner to reduce condensation; it closes with a clip and four ties. It’s clean and simple for short, low‑risk legs, delivering roughly two to three hours of useful cold, depending on insulation and ambient heat.

Why it matters to you: The product was designed for cold therapy, not long‑haul logistics control. For quick clinic‑to‑home trips or brief hand‑carry legs, the kimberly clark stay dry ice pack works well and keeps totes drier than a plain ice bag. For four‑hour suburban pharma routes or validated 2–8 °C lanes, switch to PCMs in a qualified shipper.

How does the 3‑layer “stay‑dry” design reduce mess?

Details: The outer fabric stays comfortable; the absorbent core captures meltwater; the inner film holds ice/water securely. Result: less sweat on labels and cartons, fewer leaks, easier cleanup. In a well‑insulated tote, you may see up to ~2.5 hours of effective chill; expect less in hot weather or soft bags. Use the ties to stop pack migration—movement accelerates warming.

| Feature Comparison | Stay‑Dry Ice Bag | Instant Cold Pack | 5 °C PCM Gel Pack | What it means for you |

|---|---|---|---|---|

| Typical duration | ~2.5 h (therapy context) | ~20 min | 6–48+ h (with qualified shipper) | Pick by route time and risk. |

| Condensation | Absorbent core reduces sweat | N/A (short) | Can sweat; requires barriering | Drier totes protect labels. |

| Best use | Short, non‑regulated legs | Emergency spot cooling | Validated 2–8 °C lanes | Match coolant to compliance. |

Practical tips that prevent excursions

-

Pre‑chill the product and tote. Don’t let the ice bag be the only cold source.

-

Tie or clip firmly and fix position. Movement = faster melt.

-

Barrier near labels. A thin pouch prevents label curl on humid days.

-

Measure your lane. Add a simple logger to confirm your real hold time.

Real‑world case: A hospital courier used two kimberly clark stay dry ice pack units in a fabric tote for 90‑minute clinic‑to‑home comfort packs. Totes stayed drier and arrivals were cold; summer runs beyond two hours pushed limits, prompting a switch to PCMs.

Can the Kimberly Clark Stay Dry Ice Pack keep 2–8 °C medicines safe?

No. Maintaining 2–8 °C for medicines requires conditioned PCMs and qualified packaging, not an unqualified ice bag. Guidance emphasizes avoiding frozen gel directly on refrigerated vaccines and preferring PCMs around 4–5 °C with proper conditioning and monitoring. Use the kimberly clark stay dry ice pack only for non‑regulated payloads or very short internal transfers.

What a safer 2–8 °C packout looks like

Core build: Qualified insulation + 5 °C PCM bricks conditioned to spec + logger near product core. Many vendors offer 3–7 °C ranges; choose to fit your lane. Pair with pre‑chilled product and verify with data. This is the compliant, auditor‑friendly route—and it outlasts ice bags by many hours.

| Packout Element | Purpose | Typical Spec | Your benefit |

|---|---|---|---|

| PCM gel packs | Hold 2–8 °C tightly | 3–7 °C melt range | Predictable hold; less freeze risk. |

| Qualified shipper | Verified performance | 24–96+ hours | Documentation and repeatability. |

| Data logger | Proof of control | 1–5 min sampling | Compliance evidence and learning. |

Quick conditioning checklist (copy & use)

-

Confirm lane temp band (e.g., 2–8 °C).

-

Choose coolant: 5 °C PCM > ice for medicines.

-

Condition to spec (no visible frost for 2–8 °C).

-

Pre‑chill shipper and product.

-

Place logger, seal, label, and record packout time.

Kimberly Clark Stay Dry Ice Pack vs. gel packs, PCMs, and dry ice—who wins?

Short answer: Use the kimberly clark stay dry ice pack for short, non‑regulated legs where dryness and simplicity matter. Use PCMs for regulated 2–8 °C lanes. Use dry ice only for frozen goods with proper ventilation and labels (UN 1845, Class 9) per carrier rules.

Decision matrix you can apply today

| Scenario | Stay‑Dry Ice Bag Fit? | Why | Better choice |

|---|---|---|---|

| 60–90 min clinic‑to‑home comfort packs | Yes | Short route; ties prevent slippage | — |

| 4‑hour suburban pharma route (2–8 °C) | No | Needs validated 2–8 °C packout | 5 °C PCM + qualified shipper |

| Frozen food, 6+ hours | No | Requires sublimating coolant | Dry ice + compliant labels |

Tip: If you must place an ice bag near labeled cartons, use a barrier pouch so condensation never touches labels. Build a simple “blue tote” SOP so staff recognize non‑regulated ice‑bag runs at a glance.

Where does the Kimberly Clark Stay Dry Ice Pack fit in last‑mile workflows?

Best fit: Clinic‑to‑home, staff carry, or inside insulated totes for ≤2 hours—comfort items, non‑regulated perishables, or to augment a refrigerated vehicle on the door‑to‑door leg. The four ties and clip reduce leaks and slippage, and the absorbent middle limits sweat.

A simple self‑assessment tool (interactive)

Answer and total your points:

How do you condition coolants—and where does the Stay Dry pack fit?

Do this: Condition PCMs to their stated melt point (often ~5 °C for 2–8 °C shipping). Pre‑chill shipper and product. Log with a calibrated device. Keep the kimberly clark stay dry ice pack for short, non‑regulated runs or as a supplement during hand‑carry steps.

Field‑proven workflow you can copy

-

Staging rack in a 5 °C refrigerator for PCM bricks; log in/out times.

-

Visual check for frost (none for 2–8 °C use).

-

Fill stay‑dry bag with cubes, purge air, clip, wipe, tie into place; treat route time as ≤2 hours unless measured otherwise.

2025 Cold Chain Packaging: Developments and Trends

Trend overview: Refrigerated (2–8 °C) lanes continue to dominate pharma volume, with GLP‑1 therapies keeping demand high. Reusable systems and recyclable liners are gaining ground, and policy pressure on claims like “recyclable” is increasing. Vendors broaden 3–7 °C PCM gel portfolios, improving coverage and durability versus rigid bottles. Plan capacity and inventory accordingly.

Latest progress at a glance

-

2–8 °C still leads: Plan PCM stock and testing around refrigerated lanes.

-

Reusable uptrend: Evaluate reverse‑logistics ROI by lane density and return rates.

-

EPR momentum: Be precise in sustainability claims on liners and coolants.

Market insight: U.S. pharma cold‑chain packaging grew in 2024 and is projected to rise through 2030+. Passive packaging (insulation + PCM/dry ice) continues to dominate due to cost and reliability. Prioritize validated packouts and simple SOPs over complex, failure‑prone builds.

Frequently Asked Questions

1) How long does a kimberly clark stay dry ice pack stay cold?

Typically around 2.5 hours in therapy use, less in hot ambient or soft insulation. In insulated totes, performance improves but remains short versus PCM solutions. Validate with a logger.

2) Can I use a kimberly clark stay dry ice pack for 2–8 °C vaccines?

No. Use PCMs around 4–5 °C with qualified packaging and proper conditioning; avoid freezing risk and prove control with data.

3) Is it food‑safe?

It’s marketed for therapy, not food contact. If used near food, prevent direct contact and moisture; select gel/PCM packs with explicit food‑contact declarations when in doubt.

4) Instant cold pack vs. kimberly clark stay dry ice pack—what’s different?

Instant packs last ~20 minutes for spot cooling; the kimberly clark stay dry ice pack is reusable with ties and cleaner handling—but still not a logistics PCM.

5) When should I choose dry ice instead?

For frozen lanes only, with vented packaging and proper labels (UN 1845, Class 9) and accurate net weight per carrier rules.

Summary & Recommendations

Key points: The kimberly clark stay dry ice pack is a clean, low‑sweat ice bag ideal for short, non‑regulated legs. It does not replace PCM gels + qualified shippers for 2–8 °C routes or long grocery runs. Use ties to prevent movement, pre‑chill everything, and instrument your lanes so you know actual hold times.

Action plan:

-

Audit lanes relying on stay‑dry ice bags; flag any route >2 hours.

-

Migrate those lanes to 5 °C PCM + qualified shipper + logger.

-

For frozen, establish a dry‑ice SOP with labels and net weight steps.

-

Run a lane‑fit review with our team and lock in SOPs before peak season.

CTA: Need a lane‑by‑lane coolant plan? → Book a free consult with Tempk.

About Tempk

We’re a cold‑chain packaging and analytics team focused on validated, low‑risk solutions. We pair lane modeling with qualified shippers and PCMs to hit your targets with fewer touchpoints and lower landed cost. Our strengths: evidence‑based packouts, fast pilot‑to‑scale deployment, and practical SOPs for pharma, food, and e‑grocery. Let’s make your lanes boring—in the best way.

Ready to optimize a route? Talk with a Tempk specialist for a free lane‑fit review today.