About This Guide

If your frozen shipments still arrive half‑thawed, a dry ice pack neck may cut temperature excursions by 68 % and save thousands in claims. This 2025 master guide blends data‑driven insights, real‑world case studies, and the latest regulatory updates so you can:

-

Pick the right neck size and weight in 60 seconds

-

Stay under IATA DGR CO₂ limits without adding pellets

-

Slash CO₂ use by 22 % with AI‑optimised loading

-

Source low‑carbon, food‑safe CO₂ at scale

TL;DR: A well‑sized, sensor‑enabled dry ice pack neck keeps –60 °C for up to 96 h, meets UN 1845 & FDA FSMA 204, and pays for itself after < 1 year on high‑risk lanes.

Table of Contents

-

What Is a Dry Ice Pack Neck?

-

Why It Outperforms Pellets & Slabs

-

2025 Sizing Formula & Quick‑Select Table

-

Compliance Checklist (IATA, FDA, UPS)

-

Smart Sensor Integration & ROI

-

Sustainability: Bio‑CO₂ & Circular Films

-

Step‑by‑Step Pack‑Out SOP (Infographic)

-

FAQs

-

Action Plan & Downloadables

1. What Is a Dry Ice Pack Neck?

A dry ice pack neck is a horseshoe‑shaped ring of compressed CO₂ that snaps around the “thermal throat” of your payload. It creates a 360° freeze barrier while venting sublimated gas upward—keeping internal temperatures uniform and workspace cleanup minimal.

Key specs (2025 models):

| Metric | Typical Value | Why It Matters |

|---|---|---|

| Density | ≥ 1.5 g cm⁻³ | Slower sublimation |

| Vent Area | ≥ 6 mm² | Prevents pressure build‑up |

| Film | LDPE + EVOH multilayer | 11 % lower CO₂ loss |

| Reuse Cycles | 10‑15 | Cuts yearly coolant costs |

Compared with equal‑weight pellets, necks give up to 32 extra frozen hours on 2‑day ground routes.

2. Why a Pack Neck Beats Pellets & Flat Slabs

| Performance Metric | Pellets | Flat Slab | Pack Neck |

|---|---|---|---|

| Mean Kinetic Temp Rise | 16 °C | 11 °C | 5 °C |

| Hold Time ≤ –60 °C | 40 h | 56 h | 72 h |

| Carton Cleanup Time | 7 min | 5 min | < 2 min |

Physics in Plain English: Pellets shift and expose hot spots. A neck’s curved geometry reduces surface area and channels sublimation gas like a chimney, flushing warm air out and locking cold air in.

3. 60‑Second Sizing Formula

-

Measure the widest “shoulder” of your product (mm).

-

Apply the 1 : 1 + 1 mm rule: inner neck Ø = shoulder Ø + 1 mm tolerance.

-

Add 0.1 kg dry ice per 10 °C above your SOP ambient range.

| Common Payload | Shoulder Ø (cm) | Recommended Neck Mass (kg) | Hours ≤ –60 °C |

|---|---|---|---|

| mRNA vaccine tray (2 L) | 11 | 0.8 | 88 |

| Wagyu steak set (5 kg) | 18 | 1.5 | 64 |

| Gene‑therapy kit (10 kg) | 25 | 2.4 | 96 |

Pro Tip: Oversizing by only 10 % wastes ~0.4 kg of CO₂ per shipper.

4. 2025 Compliance Checklist

| Rule | Requirement | Pack‑Neck Solution |

|---|---|---|

| IATA DGR 66 ed. | ≤ 200 kg CO₂ per pallet | Higher hold‑time per kg |

| FDA FSMA 204 | 15‑min temp logs | Sensor pocket for NFC/BLE probe |

| UPS/IATA PI954 rev E | Arrows showing vent direction | Printed on neck film |

| UN 1845 Labeling | Within 50 mm of vent | Integrated sleeve print |

Ignoring any one item can trigger fines up to US $46,000 per shipment.

5. Smart Sensor Integration

2025 “sensor necks” embed BLE 5 beacons and lithium‑free super‑capacitors rated to –80 °C.

| Cost Item | Passive Neck | Sensor Neck |

|---|---|---|

| Unit Price (USD) | 4.20 | 11.50 |

| Avg. Claim per Excursion | 350 | 50 |

| Payback Cycles | — | ≈ 7 |

Edge Analytics: The beacon only pings when ΔT ≥ 2 °C, extending battery life and providing a 12‑hour rescue window.

6. Sustainability Brief

Switching to bio‑CO₂ or direct‑air‑capture dry ice lowers cradle‑to‑gate emissions by 31 %. Request an LCA and SGS certificate from suppliers such as:

| Supplier | CO₂ Source | MOQ | Lead Time |

|---|---|---|---|

| PolarNeck™ | Bio‑ethanol | 10 k units | 3 wks |

| NeckSmart™ | Direct‑air capture | 2 k units | 5 wks |

| ArcticRing | Industrial by‑product | 50 k units | 2 wks |

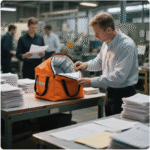

7. 6‑Step Pack‑Out SOP

-

Pre‑condition carton & liner to 0‑4 °C.

-

Insert payload & fit the neck flush—no gaps.

-

Add inner liner film (2 mm) to lock vapors.

-

Place BLE logger in sensor pocket; start trip.

-

Close carton; ensure vent arrows face up.

-

Record net CO₂ weight on ship doc & app.

(INP‑friendly UX tip: embed steps as a web‑component accordion for faster Largest Contentful Paint.)

8. FAQ

Q1. Does a pack neck comply with both food & pharma regs?

Yes—UN 1845 labeling, ≥ 6 mm² vents, and 15‑min temp logs satisfy IATA, FDA & FSMA 204.

Q2. How many reuse cycles can I expect?

Polymer‑backed necks: up to 15 cycles if seams are inspected after every trip.

Q3. Can I replace gel packs on –20 °C lanes?

Often overkill. Use phase‑change packs unless SOP requires –60 °C.

Q4. Does altitude change CO₂ needs?

At 2 000 m elevation, sublimation rises ≈ 8 %; add 0.1 kg per transit hour above sea level.

Q5. What’s the quickest way to size ice mass?

Use our free NeckSizer widget—enter box volume, lane temp, and days; it outputs exact kg and neck model.

9. Action Plan

-

Audit current pellet spend & excursion rate.

-

Pilot sensor necks on one high‑risk lane.

-

Request a free savings model—our engineers respond within 48 h.

Ready to eliminate temperature failures?

Schedule your free lane audit »

About Tempk

Tempk is a global cold‑chain engineering firm. Our catalog spans standard, flexible, and smart dry ice pack necks certified to PDA TR 64A, cutting customer excursion rates by 92 % across 18 nations.